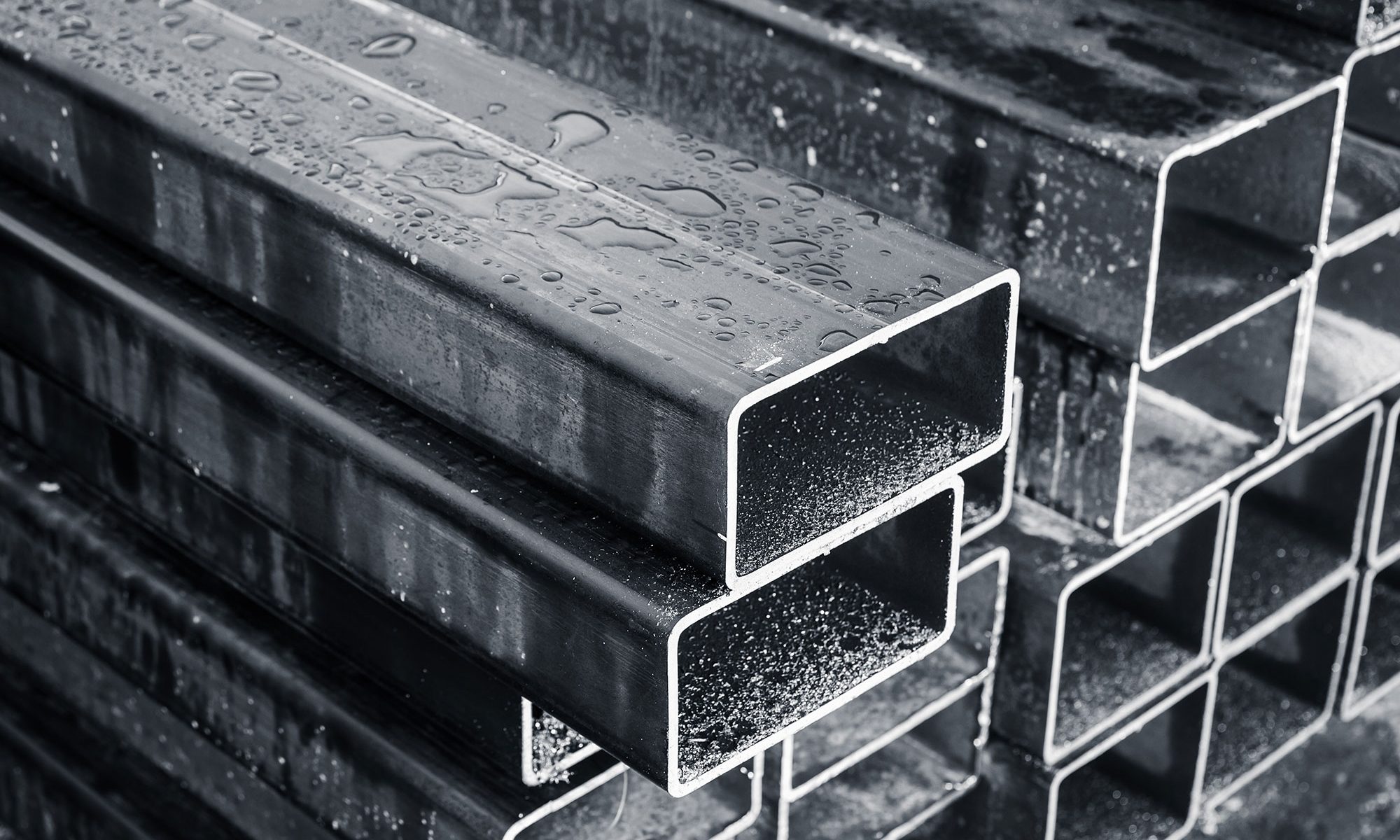

Square and rectangular tubes are the perfect choice for many applications. They’re made of strip steel and created using mechanical processes with welding to bond the edges. Since there are so many options available, there are those who struggle to select the right ones for their needs. To help, we are going to discuss what you should focus on when it comes to selecting your own tubing. Also, we will talk about how you can identify inferior rectangular and square tubes. Then, if you want the confidence of buying from the leading ERW steel tube supplier in the West Midlands, you can come to us.

Size selection

Firstly, you need to pick the right size according to your particular needs. The size of rectangle and square tubes is normally dictated by two parameters. These are height and width. Standard specifications include 25x25mm, 50x50mm, and 100x100mm. You have to consider the space limits of the place of use. The load bearing needs of the specific applications are also significant.

Thickness selection

The square/rectangular tube’s thickness decides its bending resistance and load-bearing abilities. Common thicknesses would be 1.5mm, 2.0mm, and 3.0mm. You can select these according to your specific demands.

Surface treatment

Any metal tubes can have surface treatments. With steel, the goal is to improve the anti-corrosion abilities. Standard treatment strategies include spraying and hot dip galvanising. Pick the right option to suit the specific requirements and environment.

Quality certification

This is also important. When selecting tubes, make sure yours meet the necessary standard and quality certification needs. It will guarantee reliable quality.

Price comparison

While thinking about the above factors, you should compare the prices of rectangular and square tubes. Also, consider your final purchase while focusing on performance. If you’d like to work with the greatest ERW steel tube supplier West Midlands has, let us know.

Identifying inferior tubes

One thing you can do here is look at the folding condition. You may be able to see some lines on the tube’s exterior. This fully indicates that the product is easily foldable. Low tier merchandise might have fold lines because the manufacturer has pursued high efficiency and high output when making tubes. Because of the massive degree of rolling, creases will inevitably show up.

One thing you can do here is look at the folding condition. You may be able to see some lines on the tube’s exterior. This fully indicates that the product is easily foldable. Low tier merchandise might have fold lines because the manufacturer has pursued high efficiency and high output when making tubes. Because of the massive degree of rolling, creases will inevitably show up.

Another way to identify these inferior products is by looking at the surface appearance. The surface may be uneven and feel bad. As for high calibre steel, it won’t have the same awful feeling. The cause of problems with appearance and product feel is that the manufacturer’s rolling operation has exceeded the standard. This tends to be the result of their irresponsibility and pursuit of production profits.

Finally, you are able to judge tubing quality by its gloss. Inferior products don’t have the metallic lustre and usually appear reddish. There are two leading reasons for this. One of them is that the temperature in the work area during rolling isn’t up to standard. The second is that the temperature measurement of steel lacks accuracy.

Rely on the top ERW steel tube supplier in the West Midlands

At Union Steel Tubes, we have an extensive inventory of tubing available to purchase and can take on bespoke orders too. This includes the likes of round, oval, square, and rectangular tubing. We understand the importance of having quality utensils. Thus, we ensure the tube meets the necessary quality standards.

So, if you’d like to work with the finest ERW steel tube supplier in the West Midlands, please get in touch. We can quote you for any kind of order, including large and small batches.