There are lots of potential applications for ERW tubes. Expert processing services can facilitate many of them. For example, you could choose tube bending to create a curve, an angle, or even a ring or spiral. Further fabrication and assembly can then result in even more products.

However, it is not easy to bend tube. You need the right tooling and must progress carefully. If you fail to do either of these things the result can be breakage. That will mean you need to order new tubing and have try again. There can also be massive costs and a lot of lost time for this.

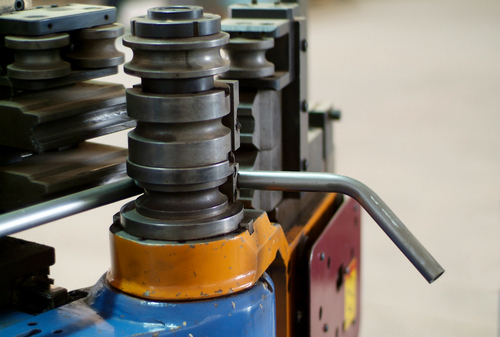

Bend tools

Selecting the right bending tools is vital. To do this though you need to ask yourself some important questions about the tubing you are using, the machinery, and the part you are trying to create.

Selecting the right bending tools is vital. To do this though you need to ask yourself some important questions about the tubing you are using, the machinery, and the part you are trying to create.

Firstly, you need to ask what material you are using. It is important to be precise here; it isn’t enough to just say something broad like steel ERW tubes or titanium. Instead, you should specify exactly what grade or alloy you are using. This will give a clearer idea of the properties and characteristics. In turn they can determine how the material will react to bending.

Secondly, you need information about the nominal dimensions of the tube. Most importantly, you need to note the diameter and wall thickness. Both will have a massive impact on bending and the tooling you need. It is also wise to note the shape of the tube.

Thirdly, you should know what the maximum degree of bend will be. This depends on the design of the part you are creating. However, it will also be affected by the type of material.

Next you need to know as much as you can about the bending machine. It isn’t enough to just look at the make and model. You need to know about its capabilities and specifications.

Finally, you need to look at quality restrictions. Bending can cause wall thinning, ovality, and some aesthetic changes. These happen with ERW tubes and other styles. So, you have to look at your design and end use to determine if they are acceptable and to what extent.

Tooling

All of this information will ensure you can create the right tooling to bend the tubing. More importantly, it will ensure the tools will fit the machine you are using.

Elongation

A vital thing to look at here is elongation. You must ensure the tube you are working with will allow the level you need to design your part. For example, if you have a steel that will only allow 15% elongation but your design calls for 25%, it is likely to break before you get near that.

Talk to us about ERW tubes

Union Steel Tubes is one of the best businesses if you need to order tubing. We are friendly experts that prioritise quality and customer service. Our goal is to ensure you choose the right products for your application, especially if you need to do things like bending and processing.

So, get in touch and let us know what you need ERW tubes for. We can advise you before placing your order.