ERW tube has uses in a wide array of industries. A common application is the transportation of resources, such as oil, water, and gas. These utensils are popular for their versatility, cost efficiency, and durability. Like any other infrastructure though, they demand regular maintenance. Without it, they can’t achieve optimal longevity and performance. We’re going to discuss the maintenance needs of these tubes and will also offer you some tips for keeping them in shape.

What are they?

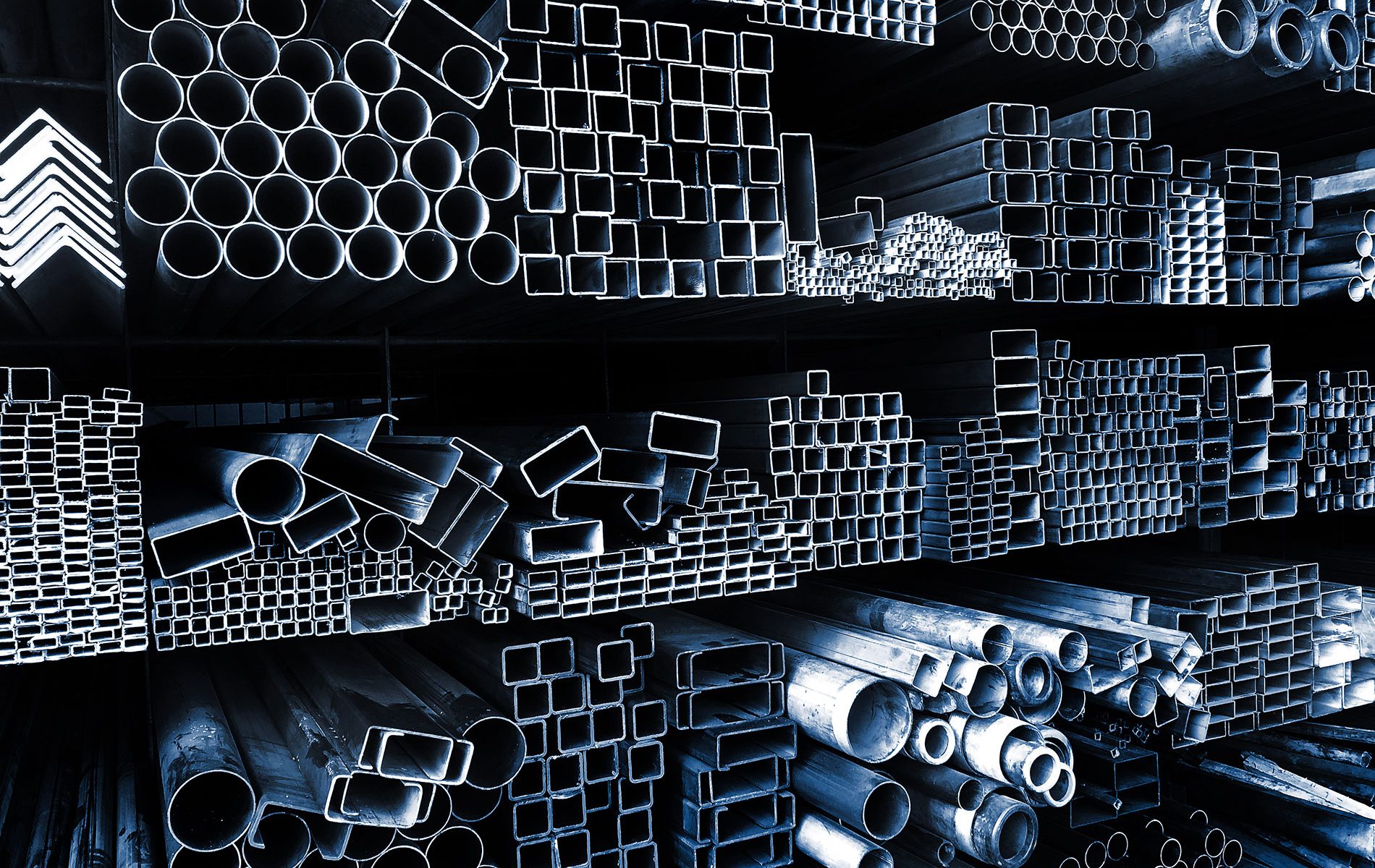

To start with, you need to understand ERW tubes. It’s necessary to do this before diving deep into the maintenance needs. You create them by rolling metal coils through multiple rollers. These shape the coil into a cylindrical tube. Then, electrical current gets passed through the tube to generate a weld. The result is a high strength product.

To start with, you need to understand ERW tubes. It’s necessary to do this before diving deep into the maintenance needs. You create them by rolling metal coils through multiple rollers. These shape the coil into a cylindrical tube. Then, electrical current gets passed through the tube to generate a weld. The result is a high strength product.

Now, we can move onto the significance of maintenance. It is vital for many reasons. First, it allows users to pinpoint and stop potential problems before they become something worse. Such action minimises the dangers of leaks or tube failures.

Second, the correct maintenance guarantees the ERW tube will carry on working effectively. This will lower energy consumption and enhance overall system performance.

Finally, a well-maintained tube will have a longer lifespan. The result will be cost savings for the user. It will also ensure less downtime.

Visual inspection

One of the principal maintenance tasks for these tubes is a visual inspection. Frequently examining the exterior can aid you in identifying signs of leaks, corrosion, or damage. Look for visible discolouration, dents, or cracks on the tube’s surface. Also, check for leakage indicators like wet spots or water stains. If you find any problems, address them ASAP to prevent further damage.

Corrosion protection

Rust is a concern for most metallic tubes, including steel ERW tube. To halt corrosion, it is critical to apply the right protective measures. This can include using paints or coatings that work as a barrier between the surrounding environment and metal. Regular touch-ups and inspections of the coatings can also help you preserve their efficiency.

Cathodic protection

What we have here is an electrochemical technique. It can safeguard metals from corrosion. It consists of the installation of impressed current systems or sacrificial anodes. They counteract the corrosive procedure. Regular maintenance and inspection of the systems will lead to them being more effective, so you need to keep on top of it.

Cleaning and flushing

ERW tubes are able to accumulate mineral deposits, sediment, or debris with time. They affect efficiency as well as performance. Regular flushing and cleaning is necessary to remove build-ups. If you flush using clean water or suitable cleaning agents it aids you in dislodging and removing accumulated materials. As a result, you will have a smooth flow, lowering the risk of blockages or clogs.

Monitor water quality

For ERW tubes employed for water supply or distribution systems, you have to monitor the quality. Water with high impurity or corrosive element levels can hasten tube degradation. Regularly testing samples can help you pinpoint problems. Treatment methods, like chemical or filtration treatments, can then preserve water quality and tube integrity.

Maintaining tube supports

Ensuring the support and alignment of ERW tubes is also crucial for longevity. You should keep an eye on this to prevent excessive sagging or stress; both can cause tube failure or deformation.

There are plenty of options for ERW tube here

At Union Steel Tubes, there are plenty of options for you to choose from. This even extends to the finishes we provide. We offer the likes of chrome or zinc plated, or deburred. We also cut the tube to the length you need.

So, please let us know if our ERW tube products interest you. We’re happy to cater for large and small orders.