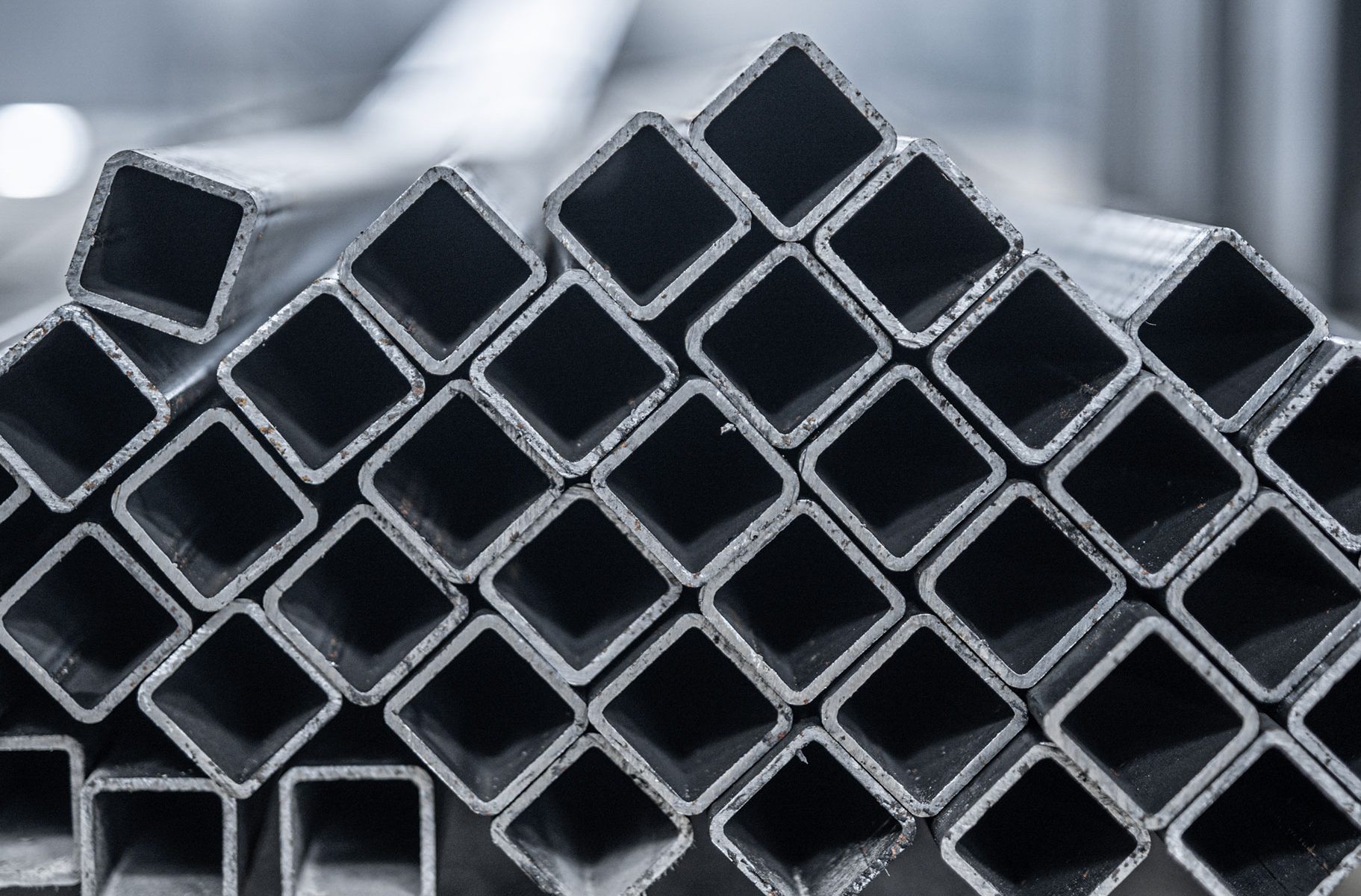

Square ERW tube has equal lengths on each side. The tubes are comprised of strip steel that is shaped mechanically and then welded. You can use them for all kinds of jobs. Before use though, you need to ensure you store them correctly. There is a proper way to do it. We are going to explain how you should handle it here.

Pick the right warehouse

Firstly, you need to pick an appropriate site and building. The warehouse or site where you store the tubes needs to be in a well-drained, clean place. Keep tubing away from factories and mines responsible for producing dust or harmful gases. All debris and weeds need removing, and you need to keep your tubes clean.

Firstly, you need to pick an appropriate site and building. The warehouse or site where you store the tubes needs to be in a well-drained, clean place. Keep tubing away from factories and mines responsible for producing dust or harmful gases. All debris and weeds need removing, and you need to keep your tubes clean.

Corrosive materials that affect steel tubes should not be near the tubing on the site because they can damage it. We’re talking about things like cement, salts, alkalis, and acids.

Usually, ordinary closed warehouses are a safe choice. These are buildings with ventilation devices, and tight windows and doors. They aim to protect the contents entirely from external elements so they are better than open warehouses. Speaking of ventilation, the warehouse must stay ventilated on sunny days. On rainy days, close it to prevent moisture. You will need to maintain an appropriate storage environment at all times.

With large steel sections and large diameter tubes, you can stack them in the open air. Medium and small size steel and medium diameter steel tubes can be placed in well-ventilated material sheds. Although, you will need to cover them. If you’re looking for excellent ERW tube products, come to us.

Stacking

The main demand for stacking is to do so according to tube specifications and varieties. This is under the conditions of guaranteeing safety and stability.

Different materials need stacking individually to stop corrosion and confusion. In addition, never store objects that might corrode steel tubes close to stacking points.

Materials of the same type need stacking individually. Do so according to the order in which you place them into storage. This is to ease the use of the first-in-first-out principle.

With sectional steel that you have stacked in the open air, there needs to be strips of stone or wooden pads underneath. As for the stacking surface, you should tilt it slightly so it makes drainage smooth. Keep your attention on the straight placement of your materials to stop deformation and bending.

For manual operation, the stacking can’t exceed 1.2m. With mechanical operation, it is 1.5m. The stack width can’t exceed 2.5m either. Between stacks, there has to be an inspection channel. It is normally 0.5m, but it depends on the material’s size and the transportation machinery.

Raise the stack

For the bottom of the stack, you should raise it. If your warehouse is on a sunny cement floor, the height needs to be 0.1m. However, for a mud floor it should be 0.2-0.5m. In the case of an open-air site, raise the cement floor by 0.3-0.5m. Raise a sand and mud surface by 0.5-0.7m so there is extra airflow.

Channel steel and angle steel needs stacking in the open air. In other words, the mouth should face down. The steel tube’s I groove exterior can’t face upward. If it does, rust and water accumulation can occur.

Packaging and the protective layer of protective materials

Steel tubing can have packaging or protective coatings to protect it. The idea is to stop the products from rusting. You need to take care not to damage either one during transportation, as well as loading and unloading.

High quality ERW tube that arrives quickly

At Union Steel Tubes, we have a wide array of ERW tube products, including square ones. To ensure quality, we have processes in place to make them accurate. Also, we have a fast delivery service that gets your orders to you on time. In some cases it can be same day.

So, if you’re looking to work with us, feel free to get in touch.