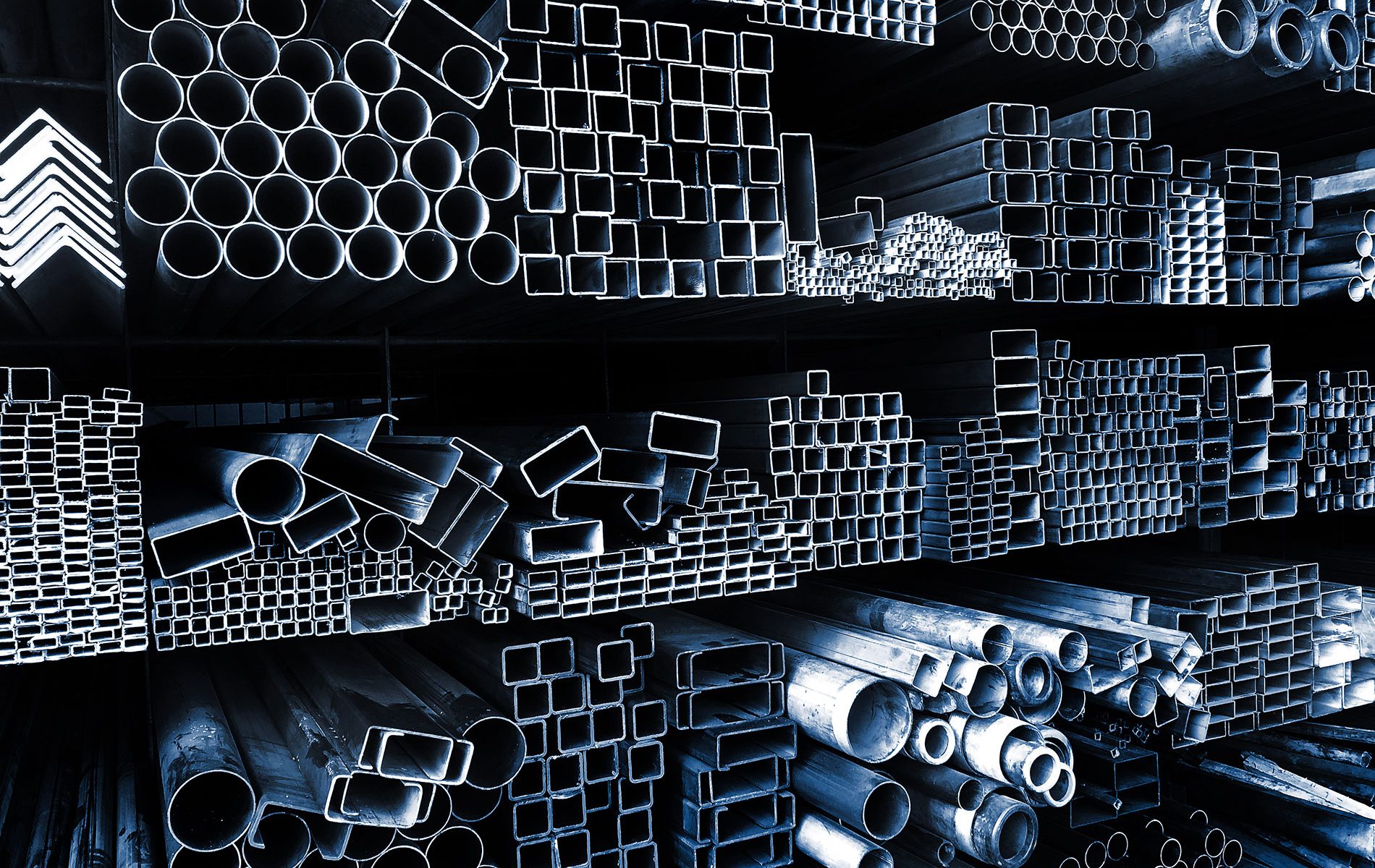

Welding and joining various pieces of tubing together is vital for creating all kinds of products. This includes handrails, furniture, vehicles, and various pieces of industrial equipment. However, there are a number of important things to think about, such as the concentration of stress and potential for failure. New research could offer a great solution though. We want to have a closer look here, then you can rely on us if you want ERW tubes.

The issue

As we said, welding and joining tubing can lead to stress concentration, especially when you apply structural loading. It can cause serious problems with things like automotive link arms and frames. Ultimately, it could end with weld failure and a serious accident.

Typical solution

The classic solution here is to use tubes with thicker walls. This provides a couple of crucial benefits.

The classic solution here is to use tubes with thicker walls. This provides a couple of crucial benefits.

Firstly, it distributes the stress across a wider surface area, reducing the concentration. Even better, it can ensure the stress is less uniform, minimising the chance of localisation in small areas.

Secondly, using ERW tubes with thicker walls will increase the overall stiffness. This is useful as it can boost the resistance to stress. Crucially, it reduces the chance of deformation.

Two options

Broadly there are two different options here. One is to select tubes that are uniformly thicker throughout the whole length. The other is to select tube that is only thicker towards the ends. The latter can offer some advantages, including reducing the weight. However, there can be drawbacks too, including the higher cycle times, extra costs, and addition to the production timescale.

A new method

The recent research we mentioned at the start of this article explores a new option for tube end thickening. The researchers claim they can increase maximum thickness by 30%. It can be done automatically, potentially providing even more value to users. Notably, the thickened tube walls can offer improvements in mechanical properties without the extra weight of using uniform thicker wall tubing. As a result, it can improve performance and save costs.

This is an area that definitely merits further research. It could be fantastic for end users in various industries, especially automotive.

Start with high quality ERW tubes

Union Steel Tubes is a company with a fantastic reputation. We supply a wide range of quality products, including different ERW tubing. You can shop with us for various sizes, diameters, and wall thicknesses. Even better, as a top steel cutting specialist, we can provide bespoke lengths for any applications.

So, if you want reliable ERW tubes, speak to us. We provide a high quality service, including advice and recommendations if you’re unsure of anything. Plus, we keep lead times as short as possible to ensure you get your tubing quickly.